An appliance’s drive system, such as the one in a washing machine, is connected to an electric motor via a motor coupling. A motor coupler, or motor coupling, employs two driving plates padded by a rubber shock absorber and is often constructed as a three-piece component. The conventional motor coupling is made to slip fit onto the output shaft and is often secured without a fastening. When transferring motor power to the transmission, the coupling inside an appliance functions similarly to the drive shaft in a car. Read More…

Our shaft couplings are the best around! Not only do we provide you with exceptional levels of customer service but we also provide you with manufacturing and a repair service that you can count on. We are also capable of providing you with special designs. That’s right! Our design team will work closely with you in order to ensure that you are getting the product that will fit your specific...

Here at Renbrandt, we take great pride in our role as a trusted provider of shaft couplings, offering a diverse range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in shaft coupling technology, we stand ready to deliver innovative solutions that excel in quality, reliability, and...

Hersey Clutch has been in business since 1963. With that kind of background and experience we have become leaders in application engineering. We specialize in finding solutions to our customer's problems regarding industrial power transmissions, brakes, clutches, couplings, universal joints, gearboxes, speed drives, friction material, crane electrification and more. Let us help you today!

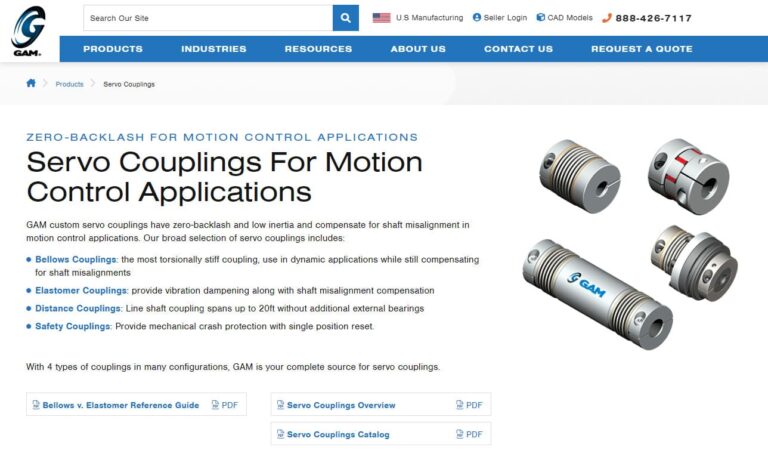

Gam Enterprises is a distributor of Jakob torsion-resistant precision couplings and safety couplings for servo drive applications. We also manufacture shaft couplings, gear couplings and rigid shaft couplings. What sets us apart from our competitors is our flexibility in making sure all of our customers' needs are met. Contact Gam today for more information.

Duraflex, Inc. is a custom and standard manufacturer providing high tech services for metal bellows, rubber bellows, edge-welded bellows, hydroformed bellows, exhaust bellows, couplings, rubber expansion joints, metal expansion joints, fabric expansion joints, pipe, tubing, hose, assemblies and flexible connectors for engineered piping systems.

More Motor Coupling Manufacturers

Types of Motor Couplings

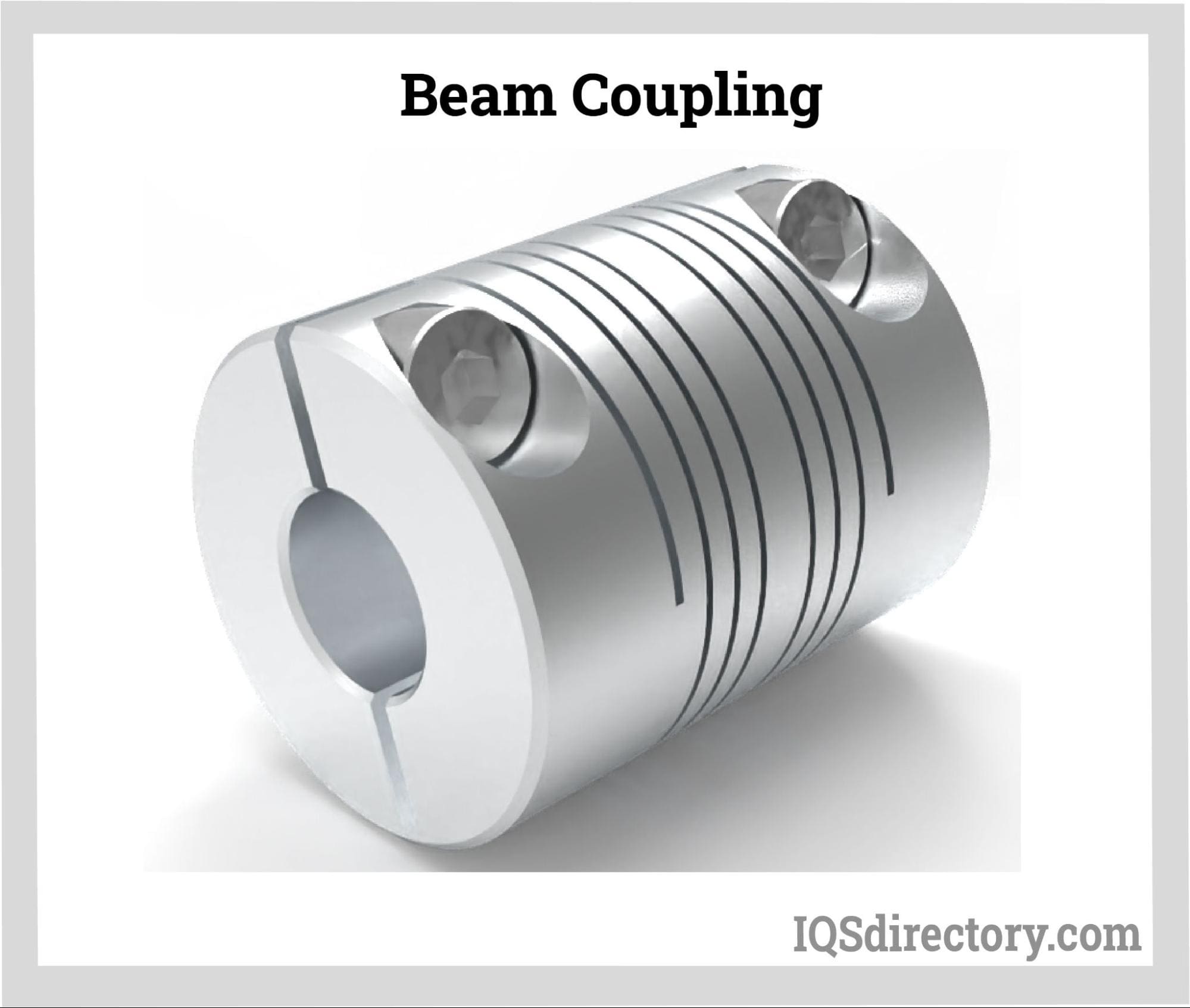

Beam Couplings

Beam couplings typically allow for parallel misalignment up to 0.025 inches and angular misalignment up to 7 degrees and have one or more helical cuts in the coupling body. They are mostly employed in applications requiring speed control, where the required torques are below 100-inch lbs. Zero backlash designs to ensure accurate placement between the available driving and driven shafts.

Beam couplings' performance and suitability for particular applications, such as those in food, medicine, and aerospace, are also influenced by the materials used in their production. Stainless steel and aluminum alloys are the most common materials. However, acetal, maraging steel, and titanium can also be used. The two most frequent robotics applications are rotary encoders connected to shafts and motion controllers.

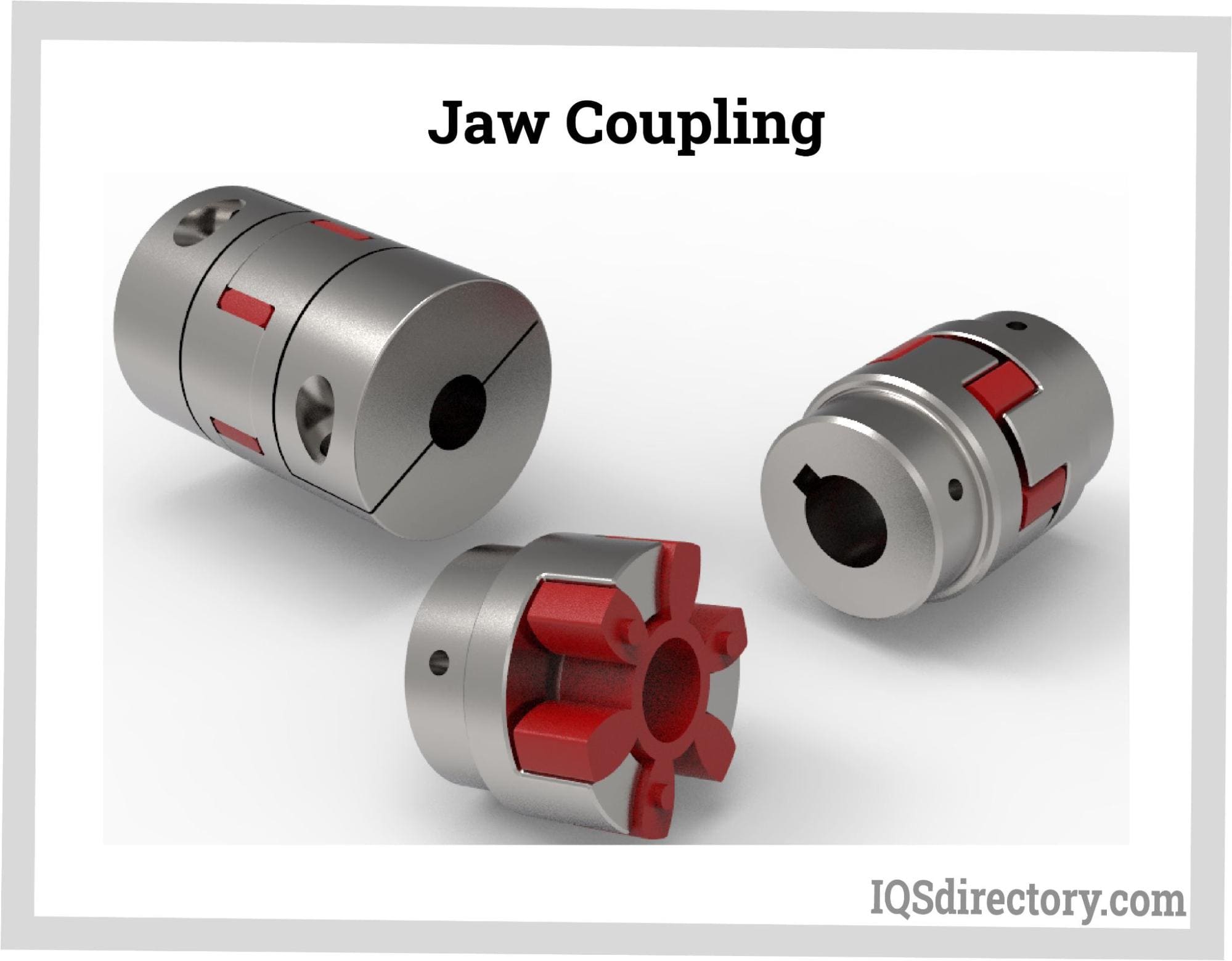

Jaw Couplings

Torque may be transmitted without backlash, thanks to the design. The average parallel and angular misalignment tolerances are 0.01 inches and 1 degree, respectively. This coupling has some damping capability thanks to elastomeric spiders, frequently offered in various durometers to provide various couplings with differing characteristics.

This coupling can transmit torque up to 1000 in. lbs and frequently performs without lubrication. A jaw coupling transmits torque by compressing an insert made of an elastomeric material that resembles a spider and is sandwiched between two interlocking jaws. Typically, the flex element is composed of bronze, polyurethane, hydrogel, or NBR. They correct misalignment, have high torque, and are useful in general-purpose applications; transmits torque; used to decrease torsion (vibration).

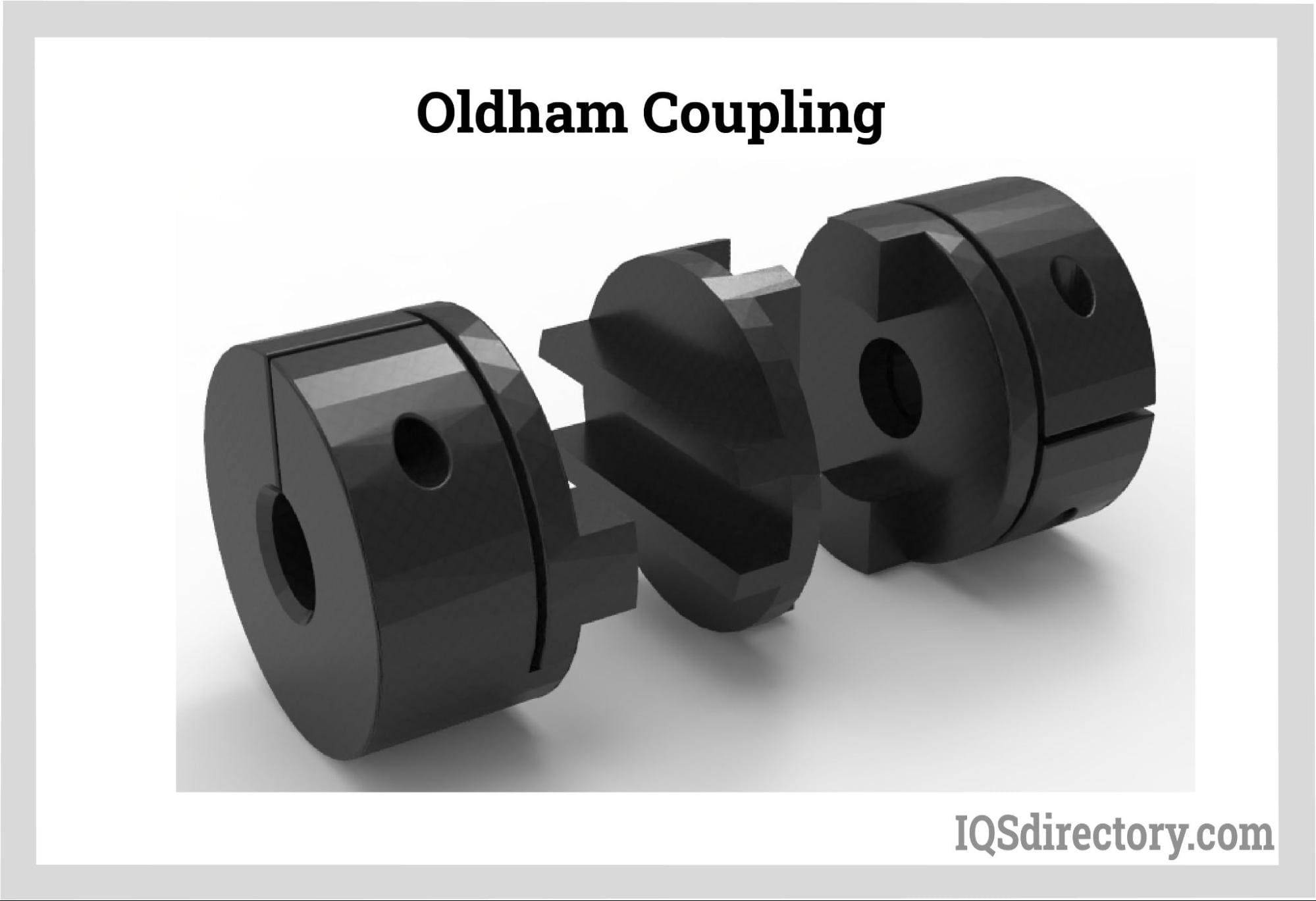

Oldham Couplings

Oldham couplings' movable element design allows them to handle significant parallel misalignment. Modern variants frequently employ an elastomer core piece in place of metal. In addition, some manufacturers assert that using cylindrical sliders rather than rectangular ones makes it possible to accept angular misalignments of up to 5 degrees. A third disk, often made of one of several different plastics, is sandwiched between the tongue-and-groove design, and two others, usually made of aluminum or stainless steel, are attached to either side of the drive. On both sides, there is a tongue-and-groove pattern.

Springs are frequently utilized to lessen the coupling's backlash. Other benefits of Oldham couplings are their small size and the capacity for electrical isolation thanks to a plastic center disk. It can serve as a coupling machine fuse. The center disks of the coupling will break first if the torque limit is exceeded, preventing torque transmission and consequent damage to more expensive machine components.

Gear Couplings

The gear coupling is the flexible coupling with the smallest diameter that transmits the most and maximum torque. There are two hubs with significant exterior gear teeth in each coupling. Two internally trimmed sleeves that are fastened together make up the hubs, which are forged.

Gear couplings tolerate angular and axial misalignment by adjusting and sliding the crown gear teeth against the mating sleeve teeth. In addition, two nearby hub/smooth flex points allow for parallel misalignment. Depending on the use, gear couplings require routine lubrication. These couplings are susceptible to lubrication failures if fitted and maintained properly.

Bellows Couplings

Applications requiring speed control can also benefit from using bellows couplings. These are made up of several metal convolutions that offer significant torsional stiffness for positioning applications. Despite having almost the same torque transmission efficiencies as beam couplings, their torsional rigidity limits the amount of angular and parallel misalignments they can allow. The considerable torsional rigidity they offer from the numerous metal fittings they include is crucial for several application conditions.

Role of Couplings in Motors

- Using a machine could cause nearby components to vibrate and shock. When a machine deviates from the recommended position, it will be hard to make appropriate use of the machine's performance if the vibration of a motor, etc., on the driving side is transferred to the ball screw, etc. Additionally, if an object strikes a machine without a connection straight from the outside, its force might be transferred to the motor, potentially damaging it. The solution to this issue is a coupling. Couplings absorb shock to keep expensive motors, etc., from being damaged.

- The main function of a coupling is to join the driven and drive shafts together. Making a machine connected with a single shaft without a coupling is challenging. Cost and accuracy issues arise from it, and because transportation and assembly are challenging, it requires more person-hours. In addition, the entire shaft must be replaced if either the driver side or the driven side of a one-piece shaft is fractured.

Choosing the Right Motor Couplings Manufacturer

To make sure you have the most beneficial outcome when purchasing motor couplings from a motor coupling manufacturer, it is important to compare at least 5 manufacturers using our list of motor coupling companies. Each motor coupling manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each motor coupling company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple motor coupling companies with the same message.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

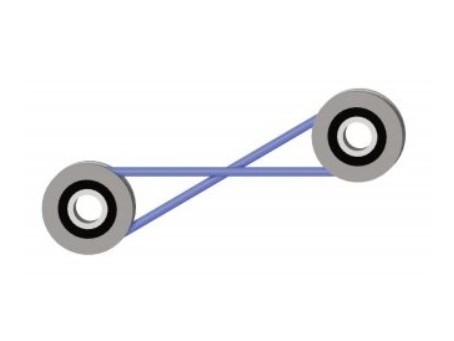

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services