Flywheel couplings and other flexible couplings are used in the transmission and engine of all varieties of vehicles. Flywheel couplings are either one or two piece engine components that are composed of a flange, hub and steel or aluminum housing. They are attached to a rotating shaft and smooth the delivery of the torque from the motor or engine. Flywheel couplings vary in size and weight, depending on the application and intended use. Read More…

Our shaft couplings are the best around! Not only do we provide you with exceptional levels of customer service but we also provide you with manufacturing and a repair service that you can count on. We are also capable of providing you with special designs. That’s right! Our design team will work closely with you in order to ensure that you are getting the product that will fit your specific...

Here at Renbrandt, we take great pride in our role as a trusted provider of shaft couplings, offering a diverse range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in shaft coupling technology, we stand ready to deliver innovative solutions that excel in quality, reliability, and...

Hersey Clutch has been in business since 1963. With that kind of background and experience we have become leaders in application engineering. We specialize in finding solutions to our customer's problems regarding industrial power transmissions, brakes, clutches, couplings, universal joints, gearboxes, speed drives, friction material, crane electrification and more. Let us help you today!

Gam Enterprises is a distributor of Jakob torsion-resistant precision couplings and safety couplings for servo drive applications. We also manufacture shaft couplings, gear couplings and rigid shaft couplings. What sets us apart from our competitors is our flexibility in making sure all of our customers' needs are met. Contact Gam today for more information.

Duraflex, Inc. is a custom and standard manufacturer providing high tech services for metal bellows, rubber bellows, edge-welded bellows, hydroformed bellows, exhaust bellows, couplings, rubber expansion joints, metal expansion joints, fabric expansion joints, pipe, tubing, hose, assemblies and flexible connectors for engineered piping systems.

More Flywheel Coupling Manufacturers

They are heavy, take up little space and are able to work efficiently and safely in temperatures from -40 to 250°F. They are mainly used within the construction and automotive industries. Construction equipment such as skid steel loaders, aerial lifts, excavators, harvesters, bucket loaders, wheeled loaders and baggage handlers all use flywheel couplings as do aerial lifts, sweepers and power mulchers.

Flywheel couplings need very little change in speed to operate correctly and are designed to carry enough energy to power a car between the firing of each cylinder. In manual transmission, a friction plate is placed between a flywheel coupling and pressure plate. This allows the engine shaft to turn the transmission. The weight and size of flywheels directly correlate with the size and weight of the vehicle. The larger, heavier truck flywheel couplings are heavier so they may store more energy and offer faster acceleration.

There are many different kinds of shaft couplings. The Oldham coupling consists of three components: two hubs and a central plastic disk. It accommodates slight parallel misalignment, while providing almost zero backlash. Backlash is the amount of lost motion due to clearance or slackness when movement is reversed and contact is re-established.

The bellows coupling has two hubs and a thin walled metallic bellows and can accommodate all three types of misalignment. Single beam couplings are usually made of a single piece of aluminum and have a system of spiral cuts that allow it to bend in order to accommodate angular misalignment. Multiple beam couplings consist of two to three overlapping beams that address problems of torsional rigidity.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

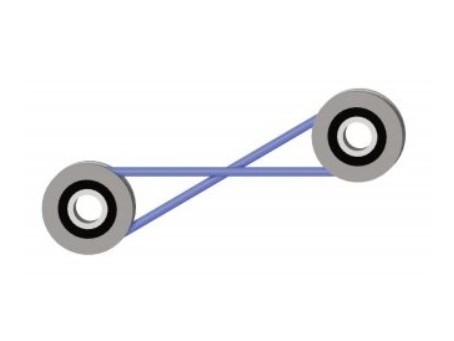

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services