Gear couplings offer efficient torque transmission in a compact mechanism and permit a high degree of axial movement. However, gear couplings require piloting and may malfunction at very high or very low torques. Crowned tooth flanks allow angular displacement to occur between each gear. Read More…

Our shaft couplings are the best around! Not only do we provide you with exceptional levels of customer service but we also provide you with manufacturing and a repair service that you can count on. We are also capable of providing you with special designs. That’s right! Our design team will work closely with you in order to ensure that you are getting the product that will fit your specific...

Here at Renbrandt, we take great pride in our role as a trusted provider of shaft couplings, offering a diverse range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in shaft coupling technology, we stand ready to deliver innovative solutions that excel in quality, reliability, and...

Hersey Clutch has been in business since 1963. With that kind of background and experience we have become leaders in application engineering. We specialize in finding solutions to our customer's problems regarding industrial power transmissions, brakes, clutches, couplings, universal joints, gearboxes, speed drives, friction material, crane electrification and more. Let us help you today!

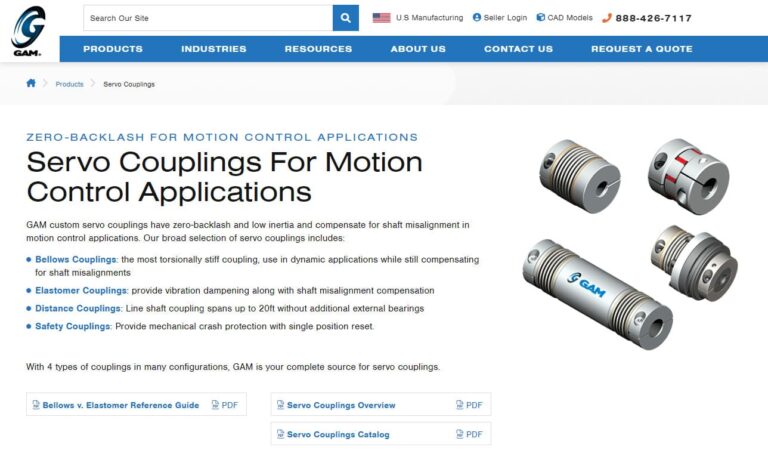

Gam Enterprises is a distributor of Jakob torsion-resistant precision couplings and safety couplings for servo drive applications. We also manufacture shaft couplings, gear couplings and rigid shaft couplings. What sets us apart from our competitors is our flexibility in making sure all of our customers' needs are met. Contact Gam today for more information.

Duraflex, Inc. is a custom and standard manufacturer providing high tech services for metal bellows, rubber bellows, edge-welded bellows, hydroformed bellows, exhaust bellows, couplings, rubber expansion joints, metal expansion joints, fabric expansion joints, pipe, tubing, hose, assemblies and flexible connectors for engineered piping systems.

More Gear Coupling Manufacturers

Two coaxial shafts can also be connected by a single joint gear coupling, known as a gear-type flexible or flexible coupling. Slight misalignments of 0.5° to 5° are tolerated by this type of gear coupling.

Gear couplings and universal joints are used in similar applications, most predominantly in the automobile industry. While gear couplings have higher torque density, universal joints induce lower vibration than gear couplings. The gear teeth in a gear coupling have high backlash, which can contribute to vibration, to allow for angular misalignment. Gear couplings are found in all rear-wheel and four-wheel driven passenger cars.

In a gear coupling, the two shafts being joined meet in the third shaft which contains gears. The teeth interlock with each other to rotate and, in doing so, they transfer torque, power and energy. Every gear coupling has differing stall speeds, which is the highest speed that the gears can turn when maximum input power is applied. Flexible shaft couplings such as gear couplings are necessary because during operation, some types of shafts tend to shift, causing misalignment.

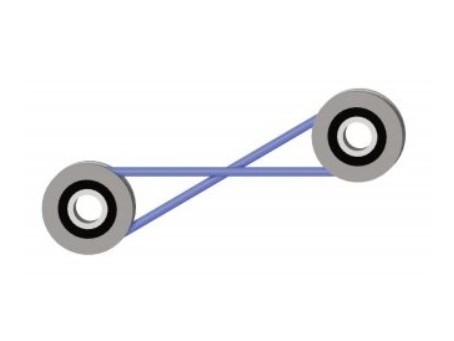

Shaft movement is caused by bumps or vibration and it results in parallel, angular or skewed shaft misalignment. Flexible shaft couplings provide efficient accommodation for moderate shaft misalignment that occurs when the shafts' axes of rotation become skewed. There are many different kinds of shaft couplings. The bellows coupling has two hubs and a thin walled metallic bellows and can accommodate all three types of misalignment.

Single beam couplings are usually made of a single piece of aluminum and have a system of spiral cuts that allow it to bend in order to accommodate angular misalignment. Multiple beam couplings consist of two to three overlapping beams that address problems of torsional rigidity. The Oldham coupling consists of three components: two hubs and a central plastic disk. It accommodates slight parallel misalignment, while providing almost zero backlash.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services