Shaft couplings provide secure connections between shafts, wheels, and rotary equipment. In addition, flexible shaft couplings are used to prevent misalignment, which can be caused by an unbalanced or bent shaft. Read More…

Our shaft couplings are the best around! Not only do we provide you with exceptional levels of customer service but we also provide you with manufacturing and a repair service that you can count on. We are also capable of providing you with special designs. That’s right! Our design team will work closely with you in order to ensure that you are getting the product that will fit your specific...

Here at Renbrandt, we take great pride in our role as a trusted provider of shaft couplings, offering a diverse range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in shaft coupling technology, we stand ready to deliver innovative solutions that excel in quality, reliability, and...

Hersey Clutch has been in business since 1963. With that kind of background and experience we have become leaders in application engineering. We specialize in finding solutions to our customer's problems regarding industrial power transmissions, brakes, clutches, couplings, universal joints, gearboxes, speed drives, friction material, crane electrification and more. Let us help you today!

Gam Enterprises is a distributor of Jakob torsion-resistant precision couplings and safety couplings for servo drive applications. We also manufacture shaft couplings, gear couplings and rigid shaft couplings. What sets us apart from our competitors is our flexibility in making sure all of our customers' needs are met. Contact Gam today for more information.

Duraflex, Inc. is a custom and standard manufacturer providing high tech services for metal bellows, rubber bellows, edge-welded bellows, hydroformed bellows, exhaust bellows, couplings, rubber expansion joints, metal expansion joints, fabric expansion joints, pipe, tubing, hose, assemblies and flexible connectors for engineered piping systems.

More Driveshaft Manufacturers

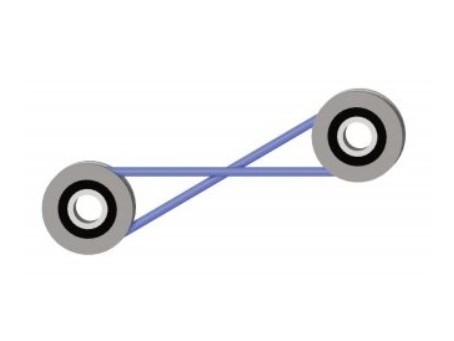

Driveshafts range in length and diameter and consist of a shaft with an assembly on either end. They are most commonly used in automobiles to transfer the power from the transmission to the wheels either through a differential or directly to the wheels, depending on whether the car is front wheel drive, all wheel drive, or rear wheel drive. In a four wheel drive vehicle, two piece driveshafts are often used and are connected with a universal joint.

Driveshafts are also used in motorcycles as an alternative to chain and belt drives; their function in motorized boats is to connect the transmission inside the vessel directly to the propeller. Driveshafts are also often components in semi-trucks, oil rigs, sewage treatment facilities, windmills, irrigation systems, paper mills, tractors, and other industrial and agricultural heavy machinery.

Driveshafts are usually hollow but large in diameter so that they are strong enough to bear torsion and shear stress, while avoiding too much additional weight. Typically, high carbon steel is used in the manufacturing of driveshafts, although this material is very heavy. Aluminum and steel alloys are being experimented with because they are a strong and lightweight alternative. New advancements in composite technology are developing alternatives to driveshaft materials.

The most common polymer matrix composites are fiberglass, carbon fiber, and carbon fiberglass hybrids. Composites are preferable over steel because they can operate at higher rotations per minute than steel of the same dimensions. However, the strengths of some composites are weaker than steel, and therefore more research is needed to make composite drive shafts widely available. The most common construction methods for these important devices are similar to bellow couplings and include electroforming, chemical deposition, mechanical forming and welding.

Electroformed drive shafts are made by adding layers of metal on a mandrel until the desired thickness is reached and the mandrel is melted away to leave behind the shaft. Chemical deposition is a similar method except that the materials are added by electrodeposition. Mechanical forming includes roll-forming or extrusion. Welded drive shafts are made by welding a series of rings or washers on both the inside and outside until smooth and seamless.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services